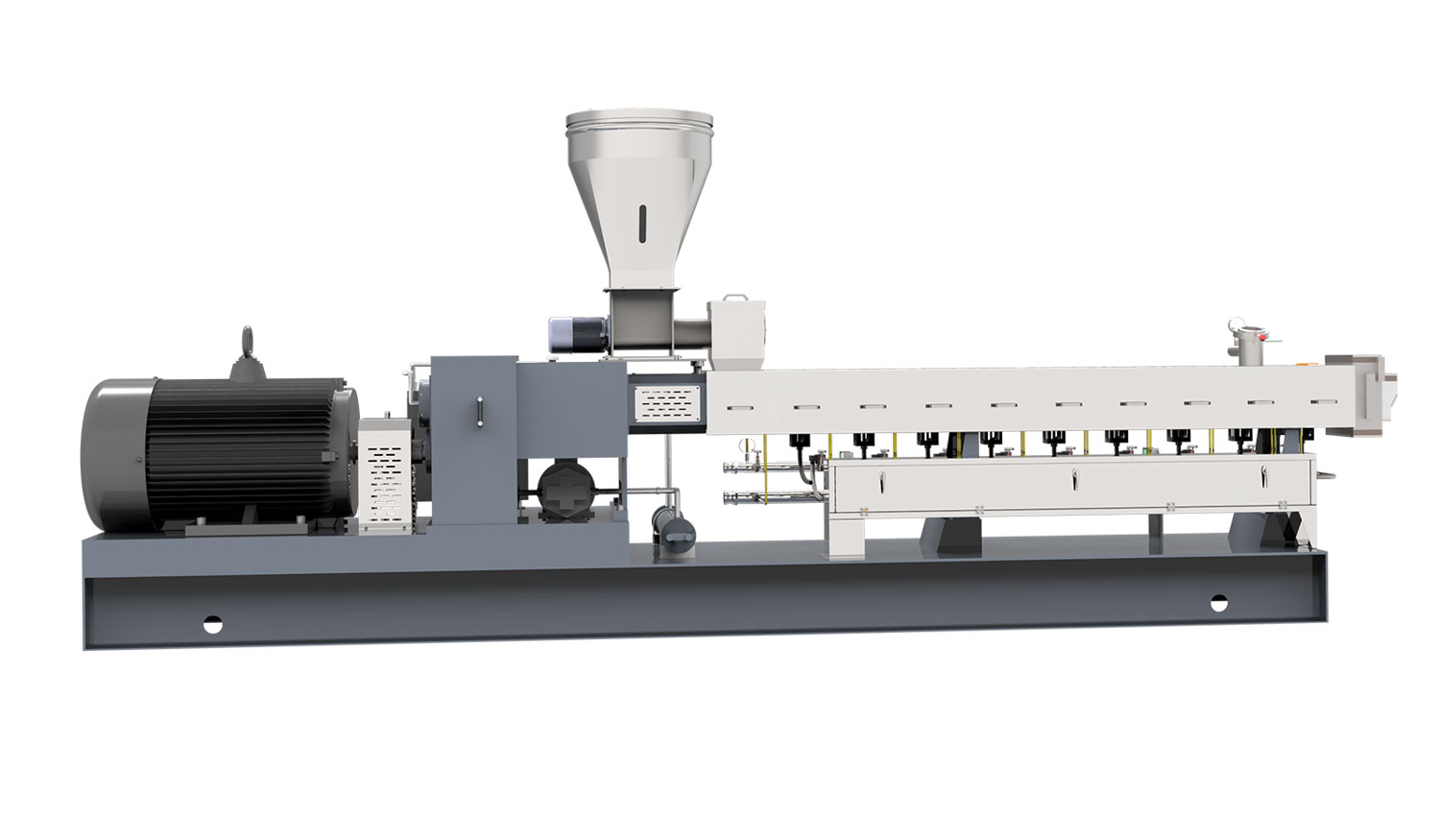

Double Screw Plastic Granulator

Double Screw Plastic Granulator

For plastic modified granulation, the main production of ABS PP PS ABS+PC PA PC PMMA PVC plastic color matching, flame retardant, enhanced, environmental protection.

The machine has high speed, high output, low energy consumption, good plasticization, strong shear and good mixing effect.

According to different performance, adjusting screw combination, using building block screw design, with self-cleaning function, cleaning screw fast, less waste.

Adopting imitation Vatu power distribution cabinet, temperature control using Ohm air instrument, solid state relay control heating line, low noise, not easy to damage.

The opening, closing, extrusion cylinder adopts independent solenoid valve and needle valve combination to control its own temperature control, temperature control is accurate, to ensure high quality of materials.

| Model | Length-diameter ratio | Motor | Rotate Speed | Screen Changer | Distribution Box | Output KG/H |

| 35B | 40:1 | 15-22kw | 400r/min | Convenient Screen changer | Imitation Witu power distribution cabinet Omron temperature control meter solid-state relay controls the heating circuit |

30-50 |

| 52B | 40:1 | 45-55kw | 400r/min | 200 Hydraumatic Single Screen Changer | 100-150 | |

| 65B | 40:1 | 90-110kw | 400r/min | 250 Hydraumatic Single Screen Changer | 250-350 | |

| 75B | 40:1 | 132-160kw | 400r/min | 300 Hydraumatic Single Screen Changer | 500-600 | |

| 52D | 44:1 | 90kw | 500r/min | Plate screen changer | 250-350 | |

| 65D | 44:1 | 132-160kw | 500r/min | Plate screen changer | 500-600 | |

| 75D | 44:1 | 200-250kw | 500r/min | Plate screen changer | 600-800 |

Leave Message Online